Global service: +86-15167681570( WeChat/Whatsapp ) E-Mail:sales@hooleamould.com

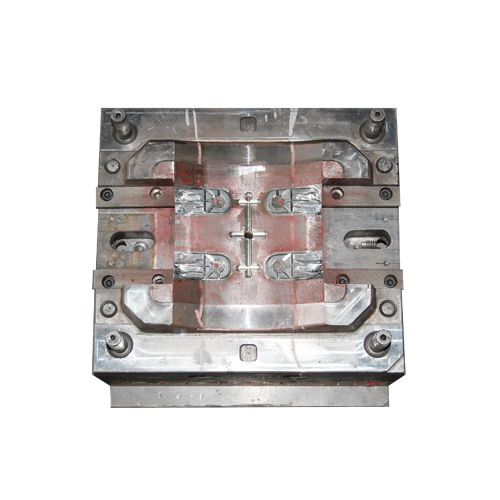

Flower pot mould -001

Category:

Flower Pot Mould

The material of the product has been screened layer by layer. No secondary raw materials are used. The material is not easy to be deformed, corroded, oxidized, and used for a long time.

Kywords:

injection mold maker china, china injection mold,injection mold company china,injection mold china

E-mail:

Global service:

Product details

Taizhou Hoolea Plastic Mould Co.,ltd Specializing in all kinds the production of injection flower pot mold

As we know the flowerpot mold has great room for development in the future, because modern people's lifestyle has slowly transformed into self-cultivation, and the cultivation of flowers has become their interest in life. Flowerpots are produced through plastic injection molds, with short production cycles and high output. Long die life. Flowerpot molds will be manufactured by more and more people.

1. The flowerpot mold can be pierced through the bottom and touch the perforation to achieve leakage and sidewall collision perforation to achieve water leakage (to prevent too much watering at once to make flowers and rot roots). The bottom leakage design directly hits the core cavity directly, and the perforation can not be too Small, because it is too small to require high-precision machining, the cost will increase. The side wall leakage design uses the cylinder core pulling to achieve the collision, which is a challenge to the complexity of the mold structure. The product production cycle will also be lengthened.

2. The economic benefits brought by flowerpot moulds. A pot of flowers may have a profit of 70%, but if a pot is added, their overall profit may be 120%. Contemporary people will pursue more and more quality lives.

Injection flower pot mould

3 flower pot mold manufacturing point

1 Early attention to product stacking height

2 Note that the draft angle prevents the appearance of the product from being cut like a knife

3 pay attention to the injection pressure, high pressure will shorten the die life.

4. Appearance of flower pots The appearance of flower pots can be made into a mirror surface, and can also be used as a skin pattern. It can also be the same as the above figure. It can also be used for thermal transfer to increase the company's LOGO.

5. Flower pot mold action, Action 1: Line four sides touch perforation through the cylinder activity, the line cavity has two valves to prevent the product from lining the cavity, the core valve + edge gas + stripper plate ejection to achieve the automatic removal of the mold, you can also use robotic hand take. Action 2: The core cavity directly touches, economical and affordable. Mold production cycle is also short. Can give customers faster and more profitable space

Hot Tags: good injection flower pot mold, China, factory, manufacturers, customized, made in China

To create a cost-effective plastic injection mold design scheme for you

Warranty for two years + lifetime maintenance + personal customization

Product Description

Plastic material: PVC,PPR,PP.PE,ABS,POM,PPH…etc

Steel of Cavity & Core: DIN 1.2316/ DIN 1.2738/DIN 1.2344 /M300/ 718/ P20..etc

Steel of Mouldbase: S50C.LkM standard…etc

Nos of Cavity: Customized

Hardness of Cavity & Core: 32-50HRC

Hardness of Wear Parts: 55-60HRC

Core pulling system: Motor /oil cylinder/ stripping plate, angel pin…etc

Mould Accessories: DME/HASCO Standard …

Cooling system: In core baffle cooling and in cavity plate chain drilling type cooling

Surface finish: Diamond polish,Texture

Molding life: 500,000-5,000,000shots

Runner: Cold or Hot Delivery time: 60work days

Packing: Export standard wooden case

Specializing in injection mold industry 20 years

The trouble with poor mold

Advantage of choose our company

Design

Design is our soul

we are specialized in mold design, absorb technology from many regions Quality Quality is our heart Our mold steels have certificates, mold life is long, mold produced by cash equipment, tolerance reaches + -0.01mm

Quality

Quality is our heart

Our mold steels have certificates, mold life is long, mold produced by cash equipment, tolerance reaches + -0.01mm

Price

Manufacturers direct sales

The price is more favorable Hesitate our manufacturing still, the source, so we always offer competitive prices

Service

3 tests, 2 years warranty, lifetime technical support

Free product design and mold design 2D/3D) Free sample delivery, three mold tests, updated production information every week Mold with one year warranty, lifetime technical support

EQUIPMENT

The company has get excellent achievement by introducing advanced equipment and technology,enforcing products art, design and manufacture.Every key steps of manufacture were strictly controlled and the quality of products were guaranteed.

See the Injection Molds We Made

Mould Making Process

EXHIBITION INFORMATON

Our company profile

Taizhou Hoolea Plastic Mould co.,ltd have 20 years experiance in making plastic moulds,We are the THE PROFESSIONAL PLASTIC MOULD MANUFACTURER AND EXPORTER IN CHINA. Based on precise tooling, high technology and top mentality mould design. Hoolea has established the main markets in America,UK,Spain,Poland,Turkey,Russia, Iran, India,Pakistan, Algeria,Nigeria and other countries and regions.

1) Location: Our company is located in the strand of East China Sea in Huangyan District of Taizhou City. We are near No. 104 National Road, Yong-Tai-Wen Highway and Huangyan Airport and next to Wenzhou and Ningbo Airports. It takes 3 hours to reach Hangzhou by car, take 3 hours by train to reach SHANGHAI by train, take 2 hours by plane or 8 hours by train to reach GUANGZHOU, The transportation is very convenient.

2) Specialization: 1. We are specialized in designing, molding and making plastic molds for autocar and motorcycle accessories, building materials, household products, package container and all kinds of plastic products. Our mold division can produce more than 40 sets molds per month. 2. Mass Production of Plastic Injection Parts We have 8 precision injection machines, ranging from 100 Grams to 20000 Grams, and are able to deal with general plastic, engineering plastic and special material according to our customers' requests.

3) Ability and Experience By introducing advanced CAE/CAD/CAM software with imported facilities, our project manager is taking care of the overall processes from order confirmation to delivery and even after-sales service. Our mold design team has had extensive experience of communicating with customers from Europe and the USA for a number of years, and always listens to our customer's requests. We can manufacture any kind of molds according to your requirements. By using well accepted high quality steel, we can produce the reliable products with standard techniques.

4) Purpose: Honesty, Dedication, Team-Spirit, Innovation, Service We sincerely welcome all domestic and foreign friends to visit our company. We will provide the most favorable prices and the best delivery to work with you, thus our most valuable customers can seize the market as fast as possible.

If more detailed information about our company is required, please do not hesitate to contact us. We are looking forward to cooperating with you.

Contact us for quote:

Taizhou Hoolea plastic mould Co., Ltd

ADD: No.101, Building 9, Yuxin small and micro Industrial Park, Xinqian Street, Huangyan District, Taizhou City, Zhejiang province,China,postcode:318020 Country/Region: China (Mainland)

Fax: +86-576-81123885

E-mail: sales@hooleamould.com

Mobile/Whatsapp/Wechat: +86-15167681570 ( Lydia Zeng)

Website: http://www.hooleamould.com

Previous

Previous

Online messge to get a quote

| Related products