Global service: +86-15167681570( WeChat/Whatsapp ) E-Mail:sales@hooleamould.com

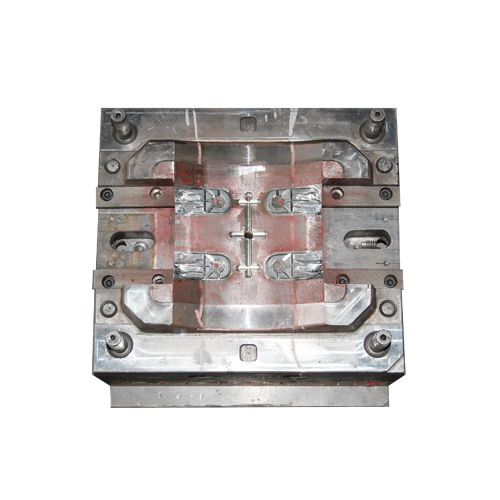

Bucket mould -007

Category:

Bucket Mould

The material of the product has been screened layer by layer. No secondary raw materials are used. The material is not easy to be deformed, corroded, oxidized, and used for a long time.

Kywords:

injection mold maker china, china injection mold,injection mold company china,injection mold china

E-mail:

Product details

injection mold maker china, china injection mold,injection mold company china,injection mold china

Product Description

Plastic material: PVC,PPR,PP.PE,ABS,POM,PPH…etc

Steel of Cavity & Core: DIN 1.2316/ DIN 1.2738/DIN 1.2344 /M300/ 718/ P20..etc

Steel of Mouldbase: S50C.LkM standard…etc

Nos of Cavity: Customized

Hardness of Cavity & Core: 32-50HRC

Hardness of Wear Parts: 55-60HRC

Core pulling system: Motor /oil cylinder/ stripping plate, angel pin…etc

Mould Accessories: DME/HASCO Standard …

Cooling system: In core baffle cooling and in cavity plate chain drilling type cooling

Surface finish: Diamond polish,Texture

Molding life: 500,000-5,000,000shots

Runner: Cold or Hot

Delivery time: 60work days

Packing: Export standard wooden case

Features:

1.High quality with pretty competitive price;

2.Good services and excellent communications;

3.Advanced technology;

4.Rich experience in export;

5.Highly qualified team with one heart.

Quality assurance:

1. Hooleamould is equiped with world advanced machine production lines with tolearance +-0.01mm

2. Quality Certificated mould steel

3. More than 20 years experiance mould worker

What we can make?

1. We are specialized in designing, molding and making plastic molds for household medical appliances, motor vehicle accessories, building materials, household appliances,pipe fitting mould,bottle/cap/preform mould, IT related products and kinds of plastic products. Our mold division can produce more than 40 molds per month.

2. Mass Production of Plastic Injection Parts

We have 8 precision injection machines, ranging from 100 Grams to 20000 Grams, and are able to deal with general plastic, engineering plastic and special material according to our customers' requests.

What we need for quotation?

If any inquiry about plastic moulds,kindly pls send us details as below:

1,Plastic components' function

Because some engineering components, it is necessary to tell the mold maker their functions or products name to make the mold maker has an idea about the plastic products.

2,Plastic material

This can help the mold maker to choose which kind of steel and which kind of injection gate…

3,Plastic components drawing or 3D file or sample picture

If you have 3D design, or 2D detailed drawings for the plastic components, then it is available for getting the quotation, if you only have the plastic samples, then please do the dimension indication on the picture and send us the clear picture for getting a more correct quotation.

4,Plastic components quantity demands

You can tell mold maker by every year, every month or every day how many pieces you need. Because the mold maker need this information to fix how many cavities on the quoted molds. And also it help mold maker to choose the correct steel, also it will help the mold maker to optimizer your mold custom cost.

5,Molding machine tonnage or injection capacity

This can help the mold maker to calculate the mold cavity Nr. According with your machine's size.

6,Custom Mold components brand

If you have special requirement for the custom mold components brand such like hot runner, hydraulic cylinder and so on, please do remember to tell mold maker when you sending an inquiry.

If any inquiry about injection products production,kindly pls send us details as below:

Plastic parts weight

Plastic material model Nr.

Plastic components color Panton Nr. Or Ral Nr.

1st shipment quantity and followed shipment quantity

Weekly, monthly or yearly quantity

Each colors quantity details

Packaging requirements

If buy mould from us, what's the guarantee?

1,Before mould delivery,we will have strict mould inspection ,and we will package the mould with spare parts.

2,If the mould broken without personal mistake operation,we will take respobsibility for it, we will make broken parts depend on design and ship to you.

Contact us:

Taizhou Hoolea plastic mould Co., Ltd

ADD: No.101, Building 9, Yuxin small and micro Industrial Park, Xinqian Street, Huangyan District, Taizhou City, Zhejiang province,China,postcode:318020

Country/Region: China (Mainland)

Telephone: +86-576-81117619

Fax: +86-576-81123885

E-mail: sales@hooleamould.com

Mobile/Whatsapp/Wechat: +86-15167681570 ( Lydia Zeng)

Website: http://www.hooleamould.com

Previous

Next

Previous

Next

Online messge to get a quote

| Related products